Published on August 2, 2023

An Electrifying Collaboration: From the Lab to the Marketplace

Columbia Engineering and Tau Motors are transforming next-generation electric vehicle technology.

AUG 02 2023

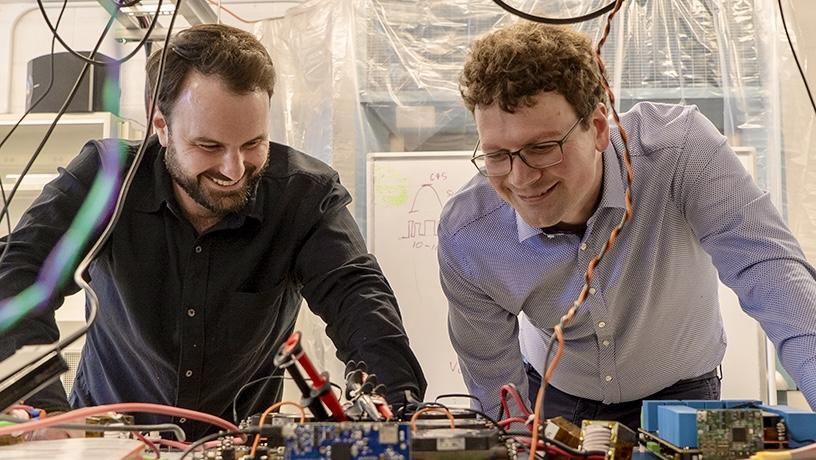

Matthias Preindl (right) and Wesley Pennington discuss software-defined power electronics in MPlab. Credit: Jane Nisselson/Columbia Engineering

Sparks flew — almost literally — when Matthias Preindl and Wesley Pennington met in 2018 through a colleague who was sure they would hit it off. Preindl, an associate professor of electrical engineering at Columbia Engineering, is a leading expert in designing next-generation power converters for electrification–from inverters for electric drives in a vehicle to onboard chargers. Pennington, the founder and CEO of Tau Motors, is focused on developing these advanced technology products as part of the company’s revolutionary technology platform. Both are determined to create efficient power conversion systems for a more sustainable future. With transportation marking the largest share of energy related emissions, the two are focused on making a meaningful and immediate impact through their work – and have big plans for the future.

The start of a close collaboration

Preindl and Pennington found a symmetry in the technology they were initially pursuing independently, as well as an aligned approach to innovation and development. The two quickly began to work together on projects in 2018, and launched an expanded collaboration just before the COVID pandemic hit. Between New York City and Silicon Valley, they obsessed over ways to leverage their expertise to expand and improve core technologies such as motors, inverters, onboard chargers, and electric vehicle (EV) drivetrains.

It was clear to both that they needed to design more modern solutions to create the next-generation of products for electrification and essential to design options that are not only high-performance, but also scalable. The pair looked to pioneer technologies that solve power conversion challenges by tightly integrating software into hardware systems to replace volatile materials and expensive components. This software-defined approach works to reduce manufacturing costs, increase efficiency, and also decrease development times to deploy new products to market.

As a result of their research collaboration, alongside their team of scientists, engineers, technologists, and operators, Tau’s platform was honored by Fast Company in 2022 with a “World Changing Idea” mention and, more recently, was placed on the publication’s 2023 top 100 Best Workplaces for Innovators list. Notably, Fast Company honored Tau as the number one “Small Company (Under 100 Employees).”

Advancing the dream for a sustainable future

As their research advanced over the years, so did their work together. They signed a portfolio license of power electronic technologies out of Preindl’s Motor Drives and Power Electronics Laboratory (MPlab) related to transportation electrification and renewables between Tau and Columbia University to extend Tau’s platform. They also developed a more formal long-term strategic partnership that further expands their research collaboration with a commitment from Tau to accelerate power electronic research and impact.

Ioannis (John) Kymissis, chair of the Department of Electrical Engineering, notes, “I think the collaboration between the MPlab and Tau follows a unique model which has the potential for significant impact in academic knowledge, the state of the art commercially, and in the experience for the students and post-docs involved.”

Tau’s funding offers significant support to advance the field for years to come and demonstrates a strong commitment to both scientific progress and the leading work at Columbia Engineering. The collaboration has already generated a number of published papers in top-ranked peer-reviewed scientific and engineering journals.

“With global warming speeding up, accelerating the industrialization of power electronic research and laboratory-scale technologies is of crucial importance. Our expertise and talent enable us to investigate next-generation ideas and pioneer cutting-edge technologies through research,” Preindl says, who credits the support of the Engineering School and Columbia Technology Ventures in recognizing the value and benefit of university-industry collaborations. “Our collaboration with Tau is a new approach for technology adoption and a streamlined lab-to-market model. It also provides us with real-world feedback and benchmarks.”

“Creating new technologies also requires new approaches to development,” Pennington adds. “Tau’s work is fundamentally multidisciplinary, requiring broad perspective and input from a variety of fields and disciplines. The innovative program we’ve developed with Dr. Preindl allows Tau to pair our leading technologists from industry with the brightest researchers in the field at Columbia to pursue novel concepts and accelerate our mission to electrify the world. Together we are able to rapidly advance both technology and the field, while also providing mentorship and opportunities for emerging scientists and engineers.”

The research side

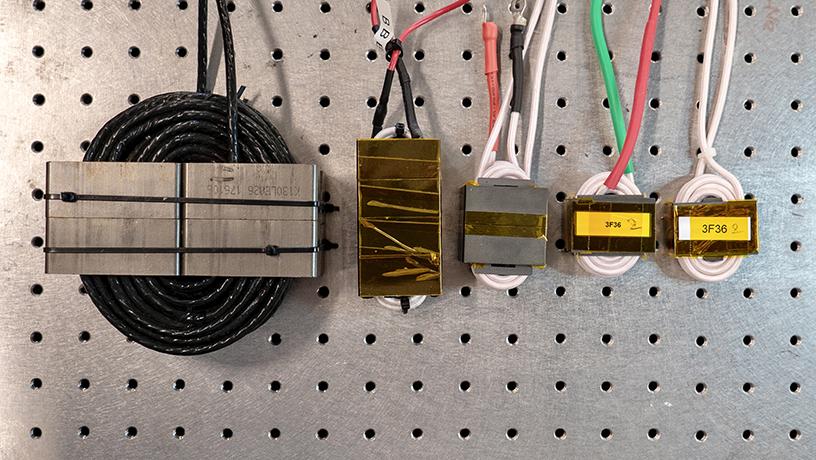

Inductor generations (2020 to 2024) for the MPlab Autoconverter Modules, the building blocks of software-defined power electronics. Credit: Jane Nisselson/Columbia Engineering

In Preindl’s lab, the team develops power electronic systems with a focus on motor drive systems and energy storage for EVs and their integration in electric grids with high penetration of renewable energy. His group is interested in designing next-generation electric powertrains–all the components that power a vehicle, from the battery to the motor. Preindl is hoping to transform the current technology by designing software-defined power electronic systems that are based on Lego-like interchangeable modules, called autoconverter modules (ACMs) which are the building blocks for soft-switching inverters and software-defined power electronics.

MPlab researchers have developed a hierarchical protocol to define and control power converters by software: ACMs form the physical layer, real-time communication is the basis for the interconnection layer, and machine learning and optimization-based estimation and control techniques enable the application layer.

The team has shown that the converters achieve a particularly high efficiency, well in excess of 99%, and reduce converter costs by solving key power electronic challenges locally in the ACM. Together with Tau, this technology is positioned to slash EV costs, increase their range, and reduce charging times. Their advancements in the design and control of these power electronic and motor drive systems also go beyond EVs, with applications in renewable energy and smart grids for higher efficiency and performance.

The commercial side

Tau is a growth-stage advanced technology company, based in the Bay Area, that designs and develops next-generation products for electrification. Pennington founded the company because he believes that the key to a more sustainable future requires modern power conversion systems to increase the security of the world’s energy. Tau has pioneered technologies that leverage the company’s software-defined hardware platform to provide industry leading scale, economics, and performance. The company’s products include innovations across electric machines, power electronics, inverters, charging systems, controllers, and beyond.

“Electrification is reshaping the world and, with that, we have an opportunity to not just rethink the technologies that exist, but also how industry partners can help us build this new future,” Pennington says. “We are excited to work alongside our partners to bring new technologies and approaches to accelerate the transition to clean energy.”

Next steps for this partnership

The pair is focused on commercialization activities with large industry partners through Tau, where Preindl also serves as chief scientist of the company’s platform. What they are especially excited about is their ambitious research roadmap that includes an emphasis on performance, scale, and economics of new electric systems. Since 2018, the work in MPlab has continued to double the power density of their autoconverter modules approximately every two years. And they don’t see that slowing down.

“We’re really fired up about this collaboration,” Preindl adds. “Our unique partnership with Tau enables us to research and develop core concepts and advance them from concept through production and commercialization. And, ultimately, we hope to make a more sustainable world for future generations.”